This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

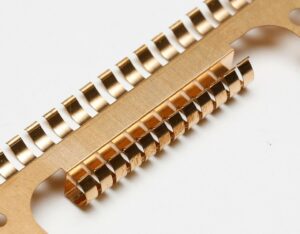

Custom Electrical Contacts

Electrical contacts, or electrical connectors, are used in the temporary connection between electrical devices or components, which can be found pretty much everywhere from a cell phone to the International Space Station.

Electrical contacts, connectors, and terminals are usually several pieces of metal bent into a shape or flat which make contact with each other and allow an electric current to flow.

They come in every possible shape and size. If you have an iPhone, they are the small parallel gold lines near the tip of a lightning cable or the four strips of metal on the inside of every USB cable.

Common Products Made With Electrical Contacts

Common products made with electrical contacts are battery components.

Beryllium Copper is a material commonly specified for electrical contacts because it is electrically conductive and can be made very springy by heat-treating after it has been bent to shape.

Unfortunately, beryllium dust is highly toxic so manufacturing methods that create airborne particulates cannot process it. Fotofab, however, uses a process to dissolve the scrap metal, meaning there is no dust. We manufacture a large number of electrical beryllium copper contacts, connectors, and terminals as a result.

RoHS Compliance Etched Contacts

Fotofab always recommends materials that are closely aligned with the longevity and health of our planet. We work with you to specify materials that comply with RoHS. If you require tin/lead solder we can collaborate with you.

Fotofab has manufactured electrical contacts since our founding. Our first order was for telephone switch contacts for Western Electric, in 1967.

Regardless of your volumes, material needs, lead times, or part geometry, Fotofab’s custom electrical contacts are exactly what you need. Request a quote from the top electrical contact manufacturer around!

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core business, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Plating

- Forming

- Machining

- Stamping

- Electropolishing

- Custom Packaging

- Laser Cutting & More